Concrete Aggregates

Our site observations for a project in Barking led us to explore the use of concrete as a seamless surface across the entire ground plane.

We developed a mix using 50% site won recycled aggregates (a crushed power station) and 50% virgin Thames river gravels in varying sizes from adjacent to the site.

We also tested a large flint aggregate from further west in the Thames watercourse.

Prototypes in self-colour steel, concrete, brick, gravel.

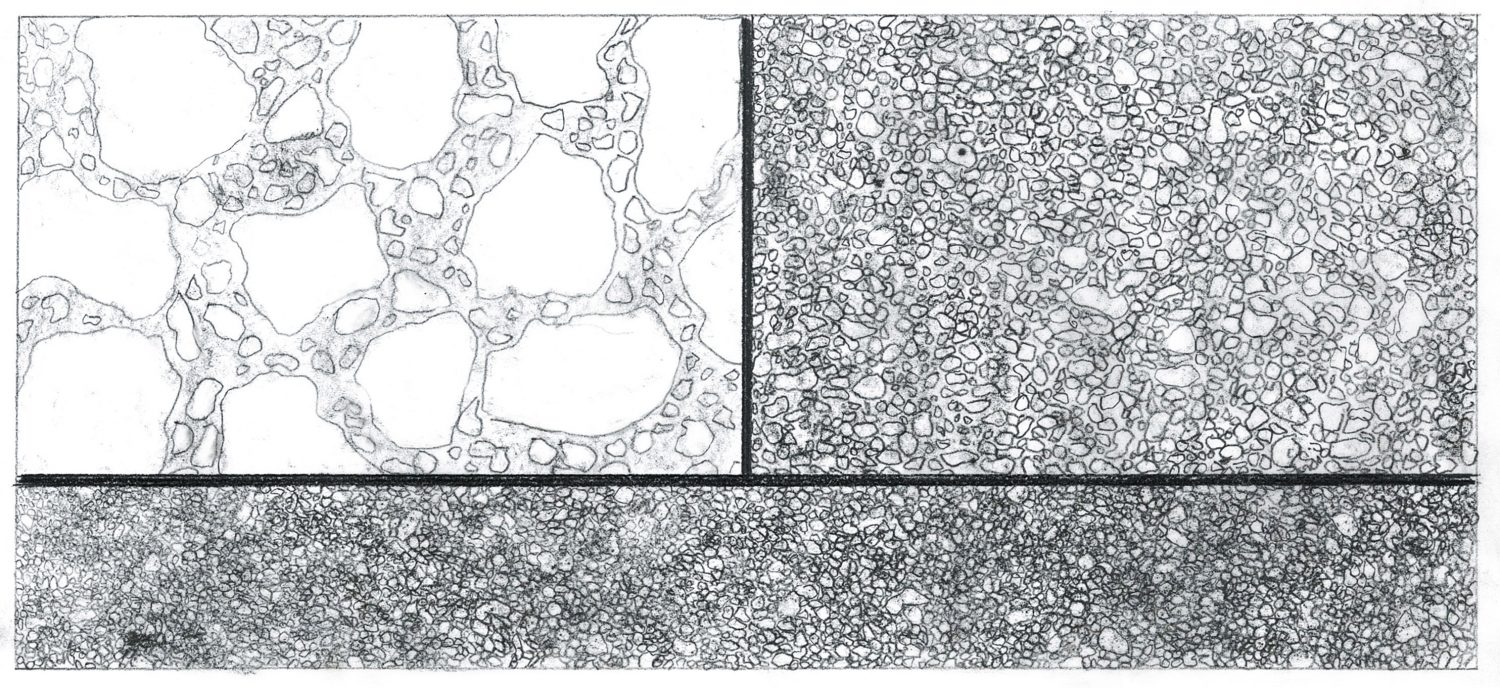

Prototype 3.01 - Wet

(Carriageway Type B):

1 part standard grey portland cement

2 parts Coarse Sharp Sand

2.4 parts 60-80mm recycled concrete

aggregate

0.8 parts 20/40mm recycled concrete

aggregate

0.8 parts 20/40mm shingle

Prototype 3.02 - Wet

(Carriageway Type A):

1 part standard grey portland cement

2 parts Coarse Sharp Sand

1.2 parts 40/60mm recycled concrete

aggregate

1.2 parts 20/40mm shingle

0.8 parts 20/40mm recycled concrete

aggregate

0.8 parts 10/20mm shingle

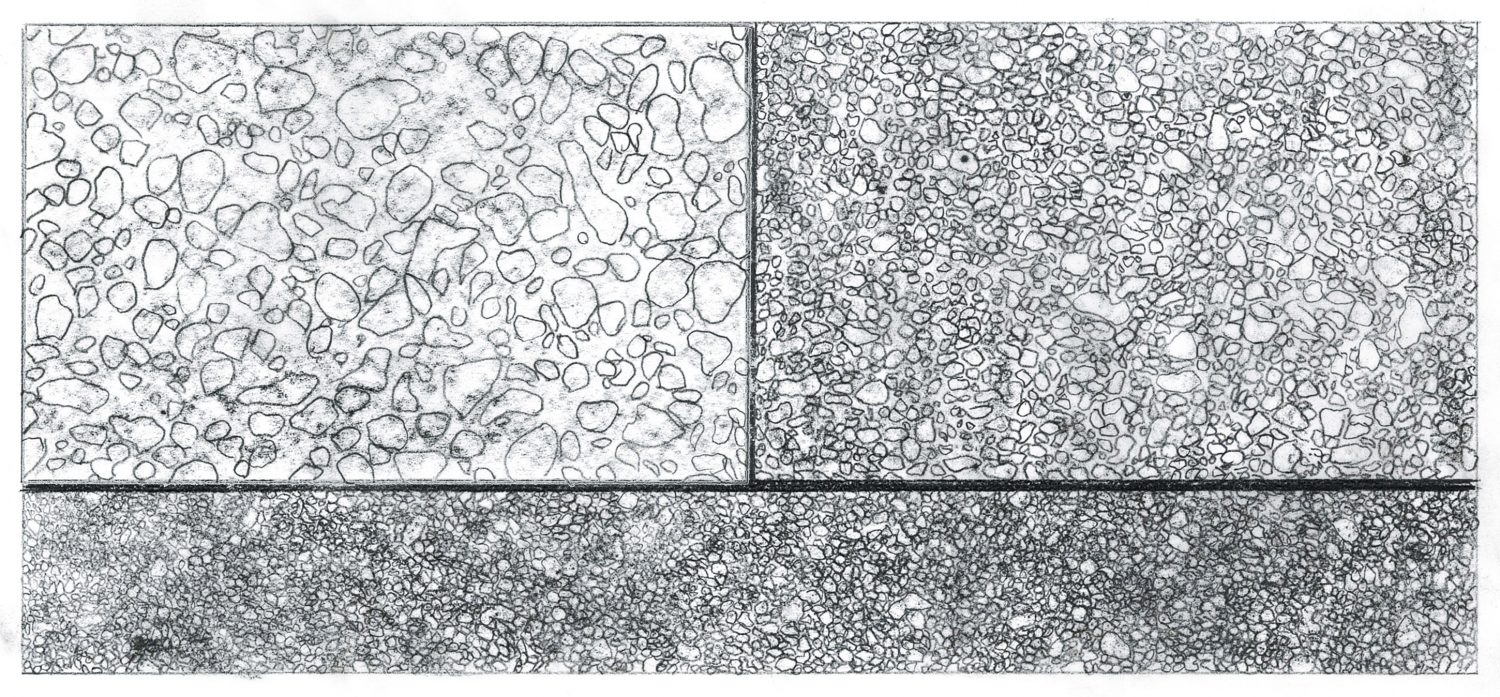

Prototype 3.03 - Wet

(Carriageway Type C):

1 part standard grey portland cement

2 parts Coarse Sharp Sand

1.6 parts 20/40mm recycled concrete

aggregate

1.6 parts 10/20mm shingle

0.4 parts 6/20mm recycled concrete

aggregate

0.2 parts 4/10mm Natural Pea Beach pebbles

0.2 parts 6mm grit

Prototype 3.04 - Wet

(Carriageway Type D):

1 part standard grey portland cement

2 parts Coarse Sharp Sand

1.6 parts 6/20mm recycled concrete aggregate

0.8 parts 4/10mm Natural Pea Beach pebbles

0.8 parts 6mm grit

0.4 parts 20/40mm recycled concrete

aggregate

0.4 parts 10/20mm shingle