Urban Mining

During Periscope's study trip to Brussels in October 2024, we visited two companies addressing the significant environmental impact of the construction sector at either end of a building/sites lifecycle, from cradle to grave.

At the cradle end, Belgium extracts 37 million tonnes of soil annually for earthworks, with some of this material needing to be disposed of in the Netherlands and Germany. Specifically, Brussels alone produces 2 million tonnes of excavated earth each year, enough to cover the entire surface area of the city. Each week, 100 trucks travel to and from construction sites for disposal, leading to rising costs and significant energy use.

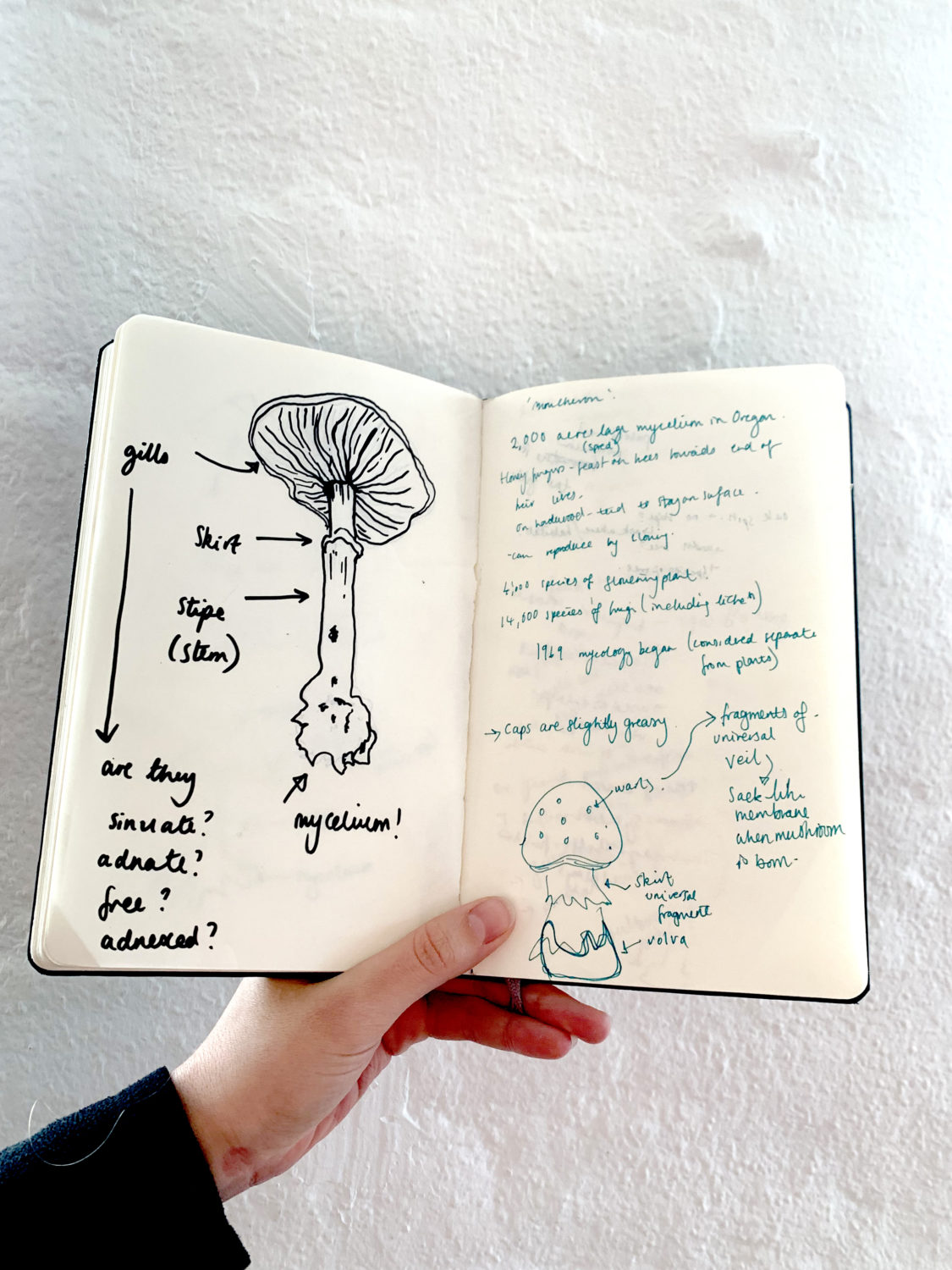

BC Materials extracted raw material storage

Rammed Earth tests at BC Materials

BC Materials intervenes in this process by creating new materials from this extracted waste, including earth plaster and paint, earth block masonry and rammed earth —about four versions of each, totalling 16 products. Product innovation is key, for instance their concrete blocks contain only 3.85% cement, compared to the traditional 9%. These blocks have the potential to replace approximately one million tonnes of internal blockwork walls used annually in Belgium.

The company's goal is to reconnect the city with its production roots, shifting focus from nightlife and waste to more sustainable operations. Their initiatives include:

- Transitioning some production and distribution from being entirely on-site to incorporating off-site operations.

- Increasing their stock from 50 tonnes on-site in 2019 to 400 tonnes.

- Engaging 1,100 people in workshops over the past five years.

- Producing their compressed bricks on an industrial scale and reducing the price by 70%, making them competitive with traditional bricks.

- Utilising spare capacity at an existing concrete block factory, which operates only 20 days per year out of its typical 200-day.

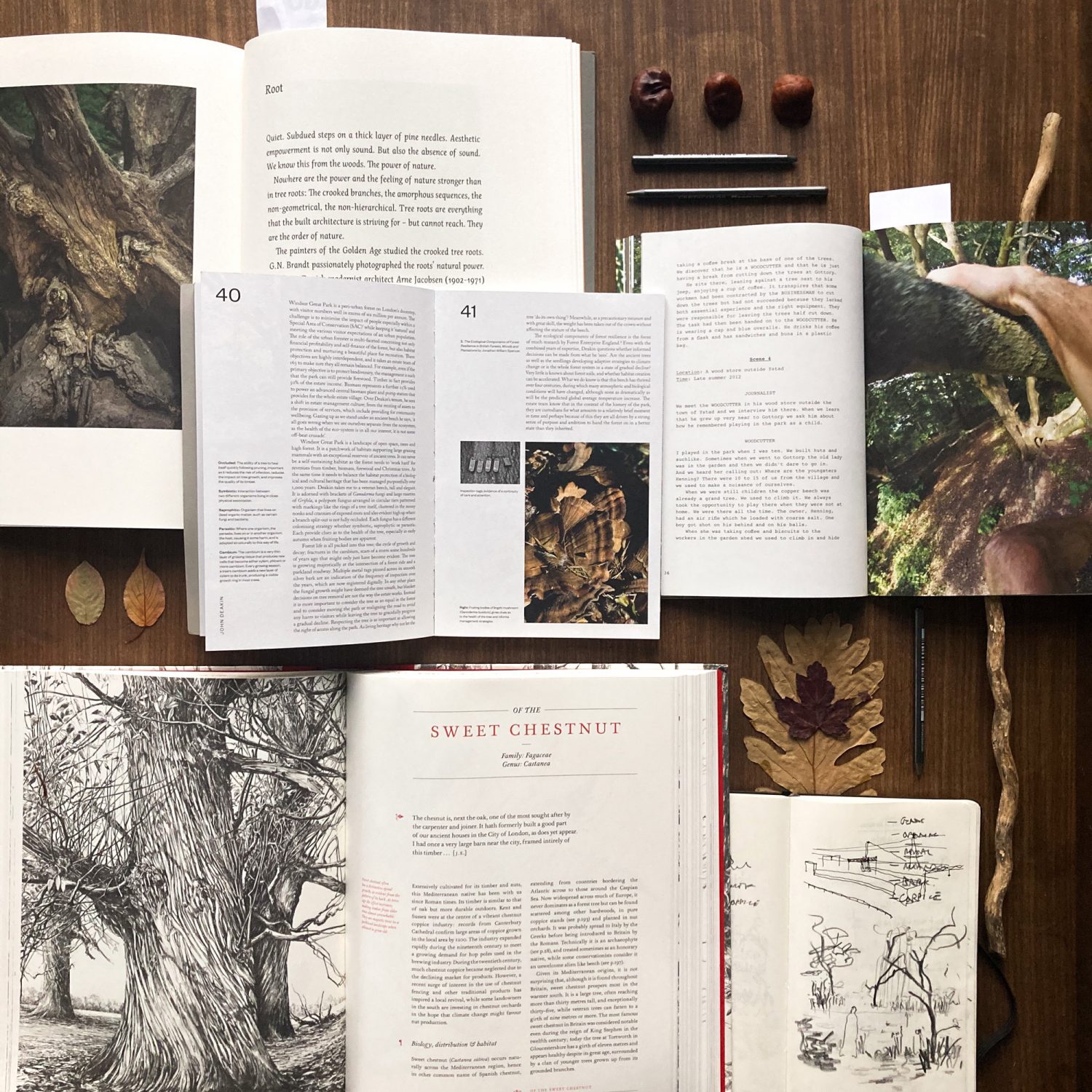

Recovered façade materials at ROTOR DC

Recovered façade materials at ROTOR DC

On the other end of the spectrum is construction and demolition waste. The amount produced annually in Belgium surged from 11 million tonnes in 2004 to nearly 20 million by 2016. The solution? Reuse.

Reusing buildings is not a new idea; in the past, it was common to disassemble structures and repurpose their materials for new functions. However, strict insurance policies regarding the quality of construction materials have rendered reusing resources from prior lives largely impractical for most construction projects. The costs of tracking the history of these materials and proving their compliance with structural integrity or fire resistance testing have, ironically, relegated them to the status of luxury items.

Inside a vast warehouse, ROTOR serves as a repository for materials salvaged from buildings scheduled for demolition. Materials are brought here to be cleaned, repaired, taxonomised, valued and released back into the market including:

Bricks

Terrazzo tiles

Granite kerbstones

Cobblestones

Paving setts

Windows

Toilet seats

Sinks

Lamps

Doors

Recovered stone copings ROTOR DC

Recovered bathroom tiles at ROTOR DC

Recovered and re-laid paving in central Brussels

With the climate clock ticking, initiatives like this are ever more urgent and require public and private backing to scale up and move from the edges of the market to its centre.